Q1: He aha ka mea welding mea?He aha ka mea e komo ai?

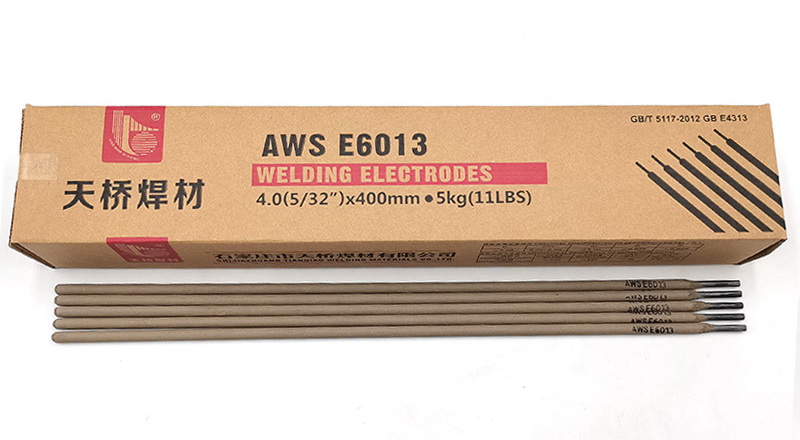

Pane: Loaʻa nā mea wiliwili i nā koʻokoʻo kuʻi, nā uwea kuʻi, nā fluxes, nā kinoea, nā electrodes, gaskets, etc.

Q2: He aha ka acid electrode?

Pane: ʻO ka uhi ʻana o ka electrode acid he nui ka nui o ka waikawa oxides e like me SiO2, TiO2 a me kahi nui o ka carbonate, a ʻo ka alkalinity o ka slag he emi ma mua o 1. Titanium electrodes, calcium titanium electrodes, ilmenite electrodes a me ka hao hao. ʻO nā electrodes nā electrodes acid āpau.

Q3: He aha ka alkaline electrode?

Pane: Loaʻa ka nui o ka alkaline electrode coating alkaline e like me ke kinikini, fluorite, a me nā mea ʻē aʻe, a loaʻa kekahi nui o ka deoxidizer a me ka mea hoʻohui.ʻO nā electrodes ʻano haʻahaʻa haʻahaʻa he alkaline electrodes.

Q4: He aha ka cellulose electrode?

Pane: He kiʻekiʻe ka cellulose ma ka electrode coating a me ka arc paʻa.Hoʻoheheʻe ia a hana i ka nui o ke kinoea e pale i ka metala weld i ka wā wili.Hoʻopuka kēia ʻano electrode i ka slag liʻiliʻi a maʻalahi ke wehe.Ua kapa ʻia ʻo ia he electrode welding vertical downward.Hiki ke welded i nā kūlana a pau, a hiki ke welded kūlou i lalo.

Q5: No ke aha e hoʻomaloʻo ʻia ai ka electrode ma mua o ke kuʻi ʻana?

ʻO nā koʻokoʻo welding e hoʻohaʻahaʻa i ka hana kaʻina hana ma muli o ka hoʻoheheʻe ʻia ʻana o ka wai, ka hopena i ke arc paʻa ʻole, hoʻonui i ka spatter, a maʻalahi hoʻi e hana i nā pores, nā māwae a me nā hemahema ʻē aʻe.No laila, pono e hoʻomaloʻo ʻia ke koʻokoʻo welding ma mua o ka hoʻohana ʻana.ʻO ka maʻamau, ʻo ka mahana maloʻo o ka electrode acid he 150-200 ℃, a ʻo ka manawa he 1 hola;ʻO ka mahana maloʻo o ka electrode alkaline he 350-400 ℃, ʻo ka manawa he 1-2 mau hola, a maloʻo a waiho ʻia i loko o kahi incubator ma 100-150 ℃ I loko, e lawe iā ia i kou hele ʻana.

Q6: He aha ka welding wire?

Pane: He uwea metala ia i hoʻohana ʻia ma ke ʻano he mea hoʻopiha metala i ka wā wili a hoʻohana ʻia no ka hoʻokele uila i ka manawa like i kapa ʻia ʻo welding wire.ʻElua ʻano: uea paʻa a me ka uea flux-cored.Hoʻohana maʻamau ka hoʻohana ʻana i ka uea kuʻihao paʻa: (GB-national standard of China) ER50-6 (papa: H08Mn2SiA).(AWS-American Standard) ER70-6.

Q7: He aha ka flux cored welding wire?

Pane: He ʻano uwea kuʻihao i hana ʻia mai nā ʻāpana kila lahilahi i ʻōwili ʻia i loko o nā paipu kila poepoe a hoʻopiha ʻia me kekahi ʻano o ka pauda.

Q8: No ke aha i pale ʻia ai ka uea flux cored e ke kinoea carbon dioxide?

Pane: Aia ʻehā ʻano o ka uea hoʻoheheʻe flux-cored: acidic flux-cored gas pale kuʻihao uea (titanium type), alkaline flux-cored kinoea hoʻoheheʻe ʻia uea (titanium calcium type), metala pauda ʻano flux-cored kinoea pale kuʻihao uea. a me ka flux-cored wili kuʻi ponoʻī.Ka home titanium type flux-cored kinoea pale kuʻihao uea maʻamau pale 'ia e CO2 kinoea;pale ʻia nā uea kuʻi flux-cored e ke kinoea hui ʻia (e ʻoluʻolu e nānā i ka kikoʻī uea flux-cored).He ʻokoʻa ka hopena metallurgical o kēlā me kēia kumulāʻau kinoea, e ʻoluʻolu mai hoʻohana i ke kinoea pale hewa.ʻO Flux-cored welding uea kinoea slag i hui pū ʻia ka pale, maikaʻi kuʻihao hoʻoheheʻe ʻia ʻana, kiʻekiʻe piha piha mechanical waiwai.

Q9: No ke aha he mau koi ʻenehana no ka maʻemaʻe o ke kinoea kalapona?

Pane: ʻO ka mea maʻamau, ʻo ke kinoea CO2 kahi huahana o ka hana kemika, me ka maʻemaʻe o 99.6% wale nō.Loaʻa iā ia nā ʻāpana o nā haumia a me ka maʻa, e lawe mai i nā hemahema e like me nā pores i ka weld.No nā huahana hoʻoheheʻe koʻikoʻi, pono e koho ʻia ke kinoea me ka maʻemaʻe CO2 ≥99.8%, me ka liʻiliʻi o nā pores i ka weld, haʻahaʻa hydrogen maʻamau, a me ke kūpaʻa maikaʻi.

Q10: No ke aha e loaʻa ai nā koi ʻenehana kiʻekiʻe no ka maʻemaʻe argon?

Pane: Aia i kēia manawa ʻekolu mau ʻano argon ma ka mākeke: argon maʻemaʻe (maʻemaʻe a puni 99.6%), argon maʻemaʻe (maʻemaʻe a puni 99.9%), a me argon maʻemaʻe kiʻekiʻe (maʻemaʻe 99.99%).Hiki ke hoʻopaʻa ʻia nā mea mua ʻelua i ke kila kalapona a me ke kila kila.Pono e hoʻohana ʻia ka argon maʻemaʻe kiʻekiʻe no ka hoʻopili ʻana i nā metala non-ferrous e like me ke alumini a me nā alumini alumini, nā titanium a me nā titanium alloys;no ka pale ʻana i ka oxidation o ka weld a me ka wela wela, ʻaʻole hiki ke loaʻa ke kiʻekiʻe kiʻekiʻe a me ka maikaʻi.

Ka manawa hoʻouna: Iune-23-2021