ʻO ke kumu ikehu o ka brazing hiki ke wela hoʻoheheʻe kemika a i ʻole ka ikehu wela indirect.Hoʻohana ʻo ia i kahi metala me kahi helu heheʻe ma mua o ka mea e welded ʻia e like me ka solder.Ma hope o ka hoʻomehanaʻana, heheʻe ka solder, a hoʻokuʻu ka hana capillary i ka solder i loko o ke āpau ma waena o nāʻaoʻao pili o ka hui e hoʻomaʻemaʻe i kaʻili o ka metala e wiliʻia i mea e hoʻokaʻawaleʻia ai ka māhele wai a me ka māhele paʻa.Interdiffusion ma waena o nā ʻāpana e hana i kahi hui brazed.No laila, ʻo ka brazing kahi hana hoʻoheheʻe paʻa a me ka wai-phase.

1. ʻO nā hiʻohiʻona a me ka hoʻohana ʻana i ka brazing

Hoʻohana ʻo Brazing i kahi huila me kahi helu heheʻe ma mua o ka metala kumu e like me ka solder.I ka wa wela, ka solder hehee ai a hoopiha a noho i loko o ka hui 'ana i ka pulupulu a me ka capillary hana, oiai ke kumu metala i loko o ka paʻa kūlana, e hilinaʻi ana i ka wai solder a me ka paʻa kumu Interdiffusion ma waena o nā mea hana i ka brazed hui.He liʻiliʻi ka hopena o Brazing i nā waiwai kino a me nā kemika o ka metala kumu, ka emi ʻana o ke koʻikoʻi a me ka deformation, hiki ke weld i nā metala like ʻole me nā ʻokoʻa nui o nā waiwai, hiki ke hoʻopau i nā welds he nui i ka manawa like, nani a nani ke ʻano o ka hui. maʻalahi nā mea hana, a liʻiliʻi ka hoʻopukapuka hana.Eia naʻe, he haʻahaʻa ka ikaika o ka hui brazed a me ka pale wela maikaʻi ʻole.

Nā noi: ʻO nā mea hana ʻoki Carbide, nā ʻāpana wili, nā papa kaʻa, nā mea hoʻololi wela, nā conduits a me nā ipu like ʻole, etc.;i ka hana ʻana i nā alakaʻi nalu microwave, nā paipu electron a me nā mea uila uila, ʻo brazing ʻo ia wale nō ke ala pili hiki.

2.ʻO ke kila kila a me ka flux

ʻO ka metala hoʻopihapiha hoʻopihapiha ka mea hoʻopihapiha hoʻopihapiha e hoʻokumu i ke poʻo brazing, a ʻo ka maikaʻi o ke poʻo brazing e pili ana i ka metala hoʻopiha piha i ka nui.Pono ka metala hoʻopiha i kahi wahi hoʻoheheʻe kūpono, hiki ke hoʻoheheʻe maikaʻi a me ka hiki ke hoʻopili ʻia, hiki ke hoʻopuʻi ʻia me ka metala kumu, a pono e loaʻa i kekahi mau waiwai mechanical a me nā waiwai kino a me nā kemika e hoʻokō ai i nā koi hana o ka hui.E like me ka ʻokoʻa o ka hoʻoheheʻe ʻana o ka metala hoʻopiha piha, hiki ke hoʻokaʻawale ʻia ka brazing i ʻelua mau ʻāpana: brazing palupalu a me ka brazing paʻakikī.

(1) Hoʻomāmā palupalu.Ua kapa ʻia ʻo Brazing me kahi helu hoʻoheheʻe ma lalo o 450 ° C he brazing palupalu, a ʻo ka mea hoʻohana maʻamau brazing filler metala he tin lead brazing, nona ka wettability maikaʻi a me ka conductivity uila a hoʻohana nui ʻia i nā huahana uila, nā mea mīkini a me nā ʻāpana kaʻa.ʻO ka ikaika o ka hui brazed he 60 ~ 140MPa.

(2) Hoʻopaʻa.ʻO ka brazing me kahi helu heheʻe ʻoi aʻe ma mua o 450 ° C ua kapa ʻia ʻo brazing, a ʻo nā mea brazing maʻamau he keleawe a me ke kumu kālā.ʻO ka hui pū me ke kālā hoʻopihapiha hoʻopihapiha he ikaika kiʻekiʻe, conductivity uila a me ka pale ʻana i ka corrosion, haʻahaʻa ka helu hoʻoheheʻe o ka metala filler, a maikaʻi ke kaʻina hana, akā kiʻekiʻe ke kumukūʻai o ka metala filler, a hoʻohana nui ʻia no ka wili. ʻāpana me nā koi kiʻekiʻe.Hoʻohana nui ʻia ʻo Brazing no nā mea hana kila a me ke keleawe me nā ikaika nui, a no nā mea hana brazing.ʻO ka ikaika hui pū ʻana o 200 ~ 490MPa,

'Ōlelo Aʻo: Pono e maʻemaʻe loa ka ʻili pili o ka mea kumu, no laila e hoʻohana ʻia ka flux.ʻO ke kuleana o ka flux ka wehe ʻana i ka ʻokikene a me ka ʻaila haumia ma luna o ka ʻili o ka metala kumu a me ka metala hoʻopihapiha, pale i ka ʻili pili o ka mea hoʻopihapiha hoʻopihapiha a me ka metala kumu mai ka oxidation, a hoʻonui i ka wettability a me ka wai capillary o ka mea hoʻopihapiha. metala.Pono e emi ka helu heheʻe o ka flux ma mua o ka metala hoʻopiha, a ʻo ka ʻino ʻana o ke koena flux i ka metala kumu a me nā hui.ʻO ka flux brazing maʻamau he rosin a i ʻole zinc chloride solution, a ʻo ka flux brazing maʻamau he hui ʻia o ka borax, boric acid a me ka alkaline fluoride.

Ma muli o nā kumu wela a i ʻole nā ʻano hana hoʻomehana hiki ke hoʻokaʻawale ʻia ʻo brazing i:ʻO ka lapalapa ahi, ka hoʻouluʻana i ka hoʻouluʻana, ke kapuahi kapuahi, ka hoʻopaʻaʻana i ke ahi, ka pale pale a pēlā aku.No ka haʻahaʻa haʻahaʻa o ka mahana wela i ka wā brazing, ʻoi aku ka liʻiliʻi o ka hopena i ka hana o ka mea hana, a liʻiliʻi hoʻi ka deformation koʻikoʻi o ka weldment.Eia naʻe, haʻahaʻa loa ka ikaika o ka hui brazed, a ʻilihune ka pale wela.

ʻO ke ʻano hoʻomehana brazing:Aneane hiki ke hoʻohana ʻia nā kumu hoʻomehana a pau e like me nā kumu wela brazing, a e like me kēia brazing ua hoʻokaʻawale ʻia.

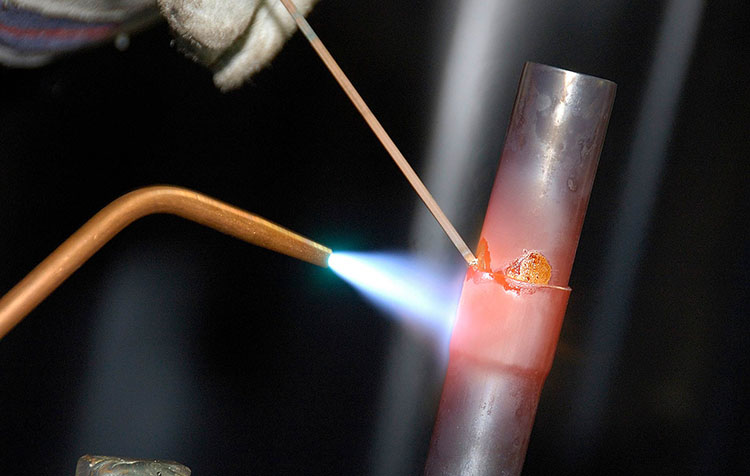

ʻO ka lapalapa ahi:ka hoʻomehana ʻana me ka lapalapa ahi, hoʻohana ʻia no ke kila kalapona, ke kila kila, ka carbide, ka hao, ke keleawe a me ke keleawe, nā alumini a me nā alumini alumini.

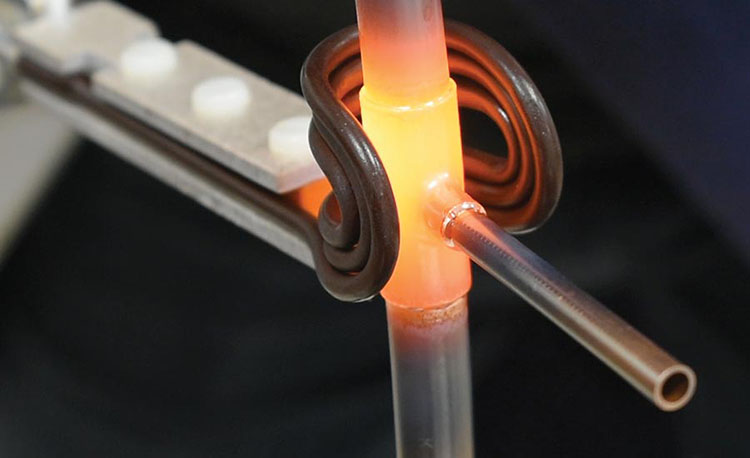

ʻO ka hoʻoheheʻe ʻana:ʻO ka hoʻohana ʻana i nā māla magnetic e hoʻohua i kahi ʻano i hoʻoulu ʻia ma ka ʻāpana o ka hoʻoheheʻe ʻana i ka wela wela, no ke ʻano symmetrical o ke kuʻi ʻana, ʻoi aku ka nui o ka brazing o ke kumu paipu.

ʻO ka hoʻopaʻa paʻa ʻana:ʻO ka'āpana hoʻoheheʻe he hapa a iʻole ka pihaʻana i ka paʻakai hoʻoheheʻeʻia aiʻole ka solder hehee, e hilinaʻi ana i ka wela o kēia mau mea hoʻoheheʻe wai e hoʻokō i ke kaʻina hana brazing, kahi iʻikeʻia e ka hoʻomehana wikiwiki, ka mahana likeʻole, ka liʻiliʻi liʻiliʻi o ka'āpana welding.

Puhi ahi:Hoʻomaʻamaʻa ʻia nā welds e kahi umu kūʻē, hiki ke pale i nā welds ma ka hoʻoheheʻe ʻana a i ʻole ka hoʻohana ʻana i nā kinoea hoʻemi a inert.

Eia kekahi, aia nā hao hao hao, brazing resistance, diffusion brazing, infrared brazing, reaction brazing, electron beam brazing, laser brazing, etc.

Hiki ke hoʻohana ʻia ʻo Brazing e weld carbon steel, stainless steel, superalloy, aluminika, keleawe a me nā mea metala ʻē aʻe, a hiki ke hoʻohui pū i nā metala like ʻole, nā metala a me nā metala ʻole.He kūpono no ka wiliwili ʻana me ka ukana liʻiliʻi a i ʻole ka hana ʻana ma ka lumi wela, ʻoi aku ka maikaʻi no ka pololei, micro a paʻakikī multi-brazed welds.

Ka manawa hoʻouna: Jul-06-2023