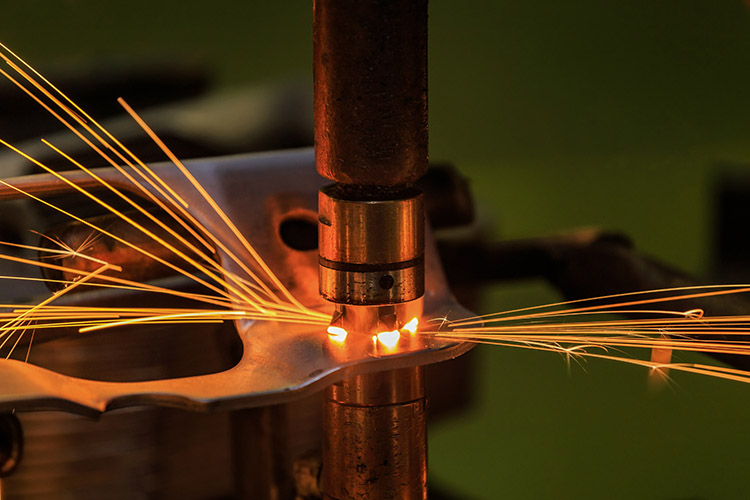

ʻO ke kuʻi kuʻi ʻana he ala kuʻi kūʻē kahi e hui ʻia ai ka weld i loko o kahi hui pūhaka a kaomi ʻia ma waena o nā electrodes ʻelua, a hoʻoheheʻe ʻia ke kumu metala e ka wela kūʻē e hana i kahi hui solder.

Hoʻohana nui ʻia ʻo Spot welding ma nā ʻano aʻe:

1. Lap hui o ka pepa hehi 'āpana, e like me ke kaʻa kaʻa, kaʻa, iʻa unahi pale o ka ohi, etc.

2. ʻO ka pā lahilahi a me ka pauku o nā hale kila a me nā hale ʻili, e like me nā paia ʻaoʻao a me nā kaupaku o nā kaʻa, nā panela pahu trailer, hui pū ʻana i nā funnel ohi, etc.

3. Nā pale, nā papa ākea a me nā kaola kea, etc.

Chana ʻino

I ka wā o ka wiliwili ʻana, hana ka weldment i kahi hui lap a kaomi ʻia ma waena o ʻelua mau electrodes.ʻO kāna mau hiʻohiʻona nui e like me kēia:

1. He pōkole loa ka manawa hoʻomehana o ka wahi pili i ka wā o ka wiliwili wahi, a wikiwiki ka wikiwiki o ka hoʻopili.

2. Hoʻopau wale ka wili ʻana i ka ikehu uila, ʻaʻole pono e hoʻopiha i nā mea a i ʻole flux, gas, etc.

3. ʻO ka maikaʻi o ka wiliwili wahi i hōʻoia nui ʻia e ka mīkini wiliwili wahi.He maʻalahi ka hana, ke kiʻekiʻe o ka mechanization a me ka automation, a kiʻekiʻe ka huahana.

4. Haʻahaʻa haʻahaʻa hana a me nā kūlana hana maikaʻi.

5. Ma muli o ka pau ʻana o ka hoʻoulu ʻana o ka welding i kahi manawa pōkole, koi ʻia kahi manawa nui a me ke kaomi, no laila ʻoi aku ka paʻakikī o ka mana o ka papahana, ʻoi aku ka nui o ka mīkini wili, a ʻo ke kumukūʻai o nā mea hana. kiʻekiʻe.

6. He mea paʻakikī ke hana i nā hoʻokolohua non-destructive ma nā hui solder.

Kaʻina hana

Pono e hoʻomaʻemaʻe ʻia ka ʻili o ka mea hana ma mua o ke kuʻi ʻana.ʻO ke ʻano hoʻomaʻemaʻe maʻamau ʻo ia ka hoʻomaʻemaʻe pickling, ʻo ia hoʻi, ka pickling i loko o ka sulfuric acid i hoʻomehana ʻia me 10%, a laila holoi i ka wai wela.ʻO ke kaʻina hana wiliwili kūikawā penei:

(1) E hoʻouna i ka hui mea hana ma waena o nā electrodes luna a me lalo o ka mīkini wiliwili wahi a hoʻopaʻa iā ia;

(2) electrification, no laila e wela a hoʻoheheʻe ʻia nā ʻili pili o nā mea hana ʻelua e hana i kahi nugget;

(3) E mālama i ke kaomi ma hope o ka ʻoki ʻia ʻana o ka mana, i ʻoluʻolu a paʻa ka nugget ma lalo o ke kaomi e hana i kahi hui solder;

(4) Wehe i ke kaomi a lawe i ka mea hana.

Nā mea hoʻohuoi

ʻO nā kumu nui e pili ana i ka maikaʻi o ka welding ka welding i kēia manawa a me ka manawa e hoʻoikaika ai, electrode pressure a shunt, etc.

1. Welding manawa a me ka manawa manawa

E like me ka nui o ka welding i kēia manawa a me ka lōʻihi o ka manawa e hoʻoikaika ai, hiki ke hoʻokaʻawale ʻia ka welding wahi i ʻelua mau ʻano: ʻano paʻakikī a me nā kikoʻī palupalu.ʻO ka ʻōlelo kikoʻī i hala i kahi au nui i kahi manawa pōkole i kapa ʻia he kikoʻī paʻakikī.Loaʻa iā ia nā pōmaikaʻi o ka huahana kiʻekiʻe, ke ola electrode lōʻihi, a me ka deformation liʻiliʻi o ka weldment.He kūpono ia no ka hoʻoheheʻe ʻana i nā metala me ka maikaʻi o ka thermal conductivity.ʻO kahi kikoʻī e hele ana i kahi au liʻiliʻi no kahi manawa lōʻihi i kapa ʻia he kikoʻī palupalu, ʻoi aku ka haʻahaʻa o ka huahana a kūpono no ka hoʻoheheʻe ʻana i nā metala e paʻakikī.

2. Electrode kaomi

I ka wā o ka welding spot, ua kapa ʻia ke kaomi ʻana e ka electrode ma ka weldment.Pono e koho pono i ke kaomi electrode.Ke kiʻekiʻe ke kaomi, hiki ke hoʻopau ʻia ka porosity shrinkage a me ka shrinkage cavity i ka wā e paʻa ai ka nugget, akā ke emi nei ke kūpaʻa pili a me ka nui o kēia manawa, e hopena i ka lawa ʻole o ka wela o ka weldment a me ka emi ʻana o ke anawaena o ka nugget o ka nugget. solder joint.Hoʻemi ʻia ka ikaika o ka hui solder.Hiki ke koho ʻia ka nui o ke kaomi electrode e like me kēia mau kumu:

(1) Ka mea o ka weldment.ʻO ke kiʻekiʻe o ka ikaika wela o ka mea.ʻOi aku ka nui o ke kaomi electrode e pono ai.No laila, i ka wiliwili ʻana i ke kila kila a me ke kila wela, ʻoi aku ka kiʻekiʻe o ke kaomi electrode ma mua o ke kila kalapona haʻahaʻa.

(2) Nā palena wiliwili.ʻOi aku ka paʻakikī o ka weld kikoʻī, ʻoi aku ka nui o ke kaomi electrode.

3. hili

I ka wā o ka wiliwili ʻana, ua kapa ʻia ke au e kahe ana mai waho o ke kaapuni nui wili.Hoʻemi ka shunt i ke kahe o kēia manawa ma kahi o ka welding, e hopena i ka lawa ʻole o ka hoʻomehana ʻana, e hopena i ka emi nui o ka ikaika o ka hui solder a pili i ka maikaʻi o ka welding.ʻO nā mea e pili ana i ke kiʻekiʻe o ka hoʻohuli ʻana i nā ʻano penei:

(1) ʻO ka mānoanoa o ka weldment a me ka spacing o nā hui solder.I ka piʻi ʻana o ka mamao ma waena o nā hui solder, piʻi ka pale ʻana o ka shunt a ke emi nei ka degere o ka shunt.Ke hoʻohana ʻia ka dot pitch maʻamau o 30-50mm, ʻo ka shunt i kēia manawa he 25% -40% o ka huina o kēia manawa, a i ka emi ʻana o ka mānoanoa o ka weldment, e emi pū ka degere o ka shunt.

(2) Ke kūlana ili o ka weldment.Ke loaʻa nā oxides a i ʻole lepo ma ka ʻili o ka weldment, piʻi ka hoʻopili ʻana ma waena o nā weldment ʻelua, a ke emi nei ka manawa ma o ka wahi welding, ʻo ia hoʻi, ke piʻi nei ke kiʻekiʻe o ka shunt.Hiki ke hoʻopili ʻia ka mea hana, hoʻoneʻe ʻia a i ʻole ʻia.

Palekana Palekana

(1) Pono e loaʻa i ka mīkini hoʻololi wāwae kahi uhi pale paʻa e pale ai i ka hoʻoulu ʻana.

(2) Pono e hoʻolako ʻia ka wahi hana me kahi baffle e pale aku ai i ka paʻi ʻana o nā hunaahi hana.

(3) Pono nā welders e hoʻohana i nā aniani pale palahalaha i ka wā e wili ai.

(4) Pono e hoʻomaloʻo ʻia kahi i waiho ʻia ai ka mīkini kuʻi, a uhi ʻia ka lepo me nā papa anti-skid.

(5) Ma hope o ka hana kuʻi ʻana, pono e ʻoki ʻia ka lako mana, a pono e hoʻonui ʻia ka hoʻololi wai anuanu no 10 kekona ma mua o ka pani ʻana.Ke haʻahaʻa ka mahana, pono e hoʻoneʻe ʻia ka wai i hōʻiliʻili ʻia ma ke ala wai e pale aku ai i ka hau.

Ka manawa hoʻouna: Iulai-31-2023