He ahawiliwili arc-cored arc?

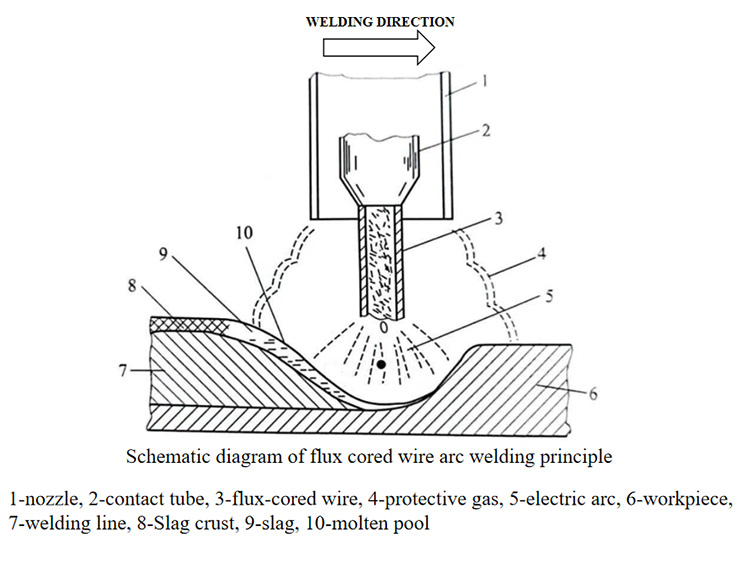

ʻO ka hoʻoheheʻe ʻia ʻana o ka uea i hoʻopaʻa ʻia ʻo Flux-cored wire arc welding he ala hoʻohana i ka arc ma waena o ka flux-cored wire a me ka mea hana e wela ai, a ʻo kona inoa Pelekane ʻo FCAW wale nō.Ma lalo o ka hana o ka arc wela, kuʻihao uea metala a me workpiece e pili ana i ka hehee ana, hana i ka weld loko, arc i mua ma hope o ka crystallization o ka weld pool huelo.

He aha ka uwea flux-cored?He aha nā ʻano o ka pahu pahu?

ʻO ka uwea wiliwili ʻo Flux-cored he ʻano uwea hoʻoheheʻe ʻia i hana ʻia e ka ʻōwili ʻana i ke kaula kila lahilahi i loko o ka paipu kila a i ʻole ka paipu kila kūikawā, e hoʻopiha ana i ka paipu me kekahi mau mea o ka pauda, a me ke kaha kiʻi.ʻO ka hoʻohui ʻana o ke kumu pauka e like me ka mea o ka electrode coating, ka mea nui i haku ʻia me ka arc stabilizing agent, slag forming agent, gas forming agent, alloying agent, deoxidizing agent, etc.

He aha ke kuleana o ka lele i loko o ka uea flux-cored?

ʻO ka hana o ka flux e like me ka mea o ka electrode coating, a aia nā ʻano like ʻole.

① ʻO ka hopena pale o kekahi mau mea i ka hoʻoheheʻe ʻana o ka flux welding, hoʻoheheʻe kekahi!ʻO ka decomposition o ka welding flux e hoʻokuʻu i ke kinoea, e hāʻawi i kekahi a i ʻole ka nui o ka pale.Hoʻoheheʻe ʻia ka mea hoʻoheheʻe i hoʻoheheʻe ʻia, e uhi ana i ka ʻili o ka kulu a me ka wai i hoʻoheheʻe ʻia, a mālama ka metala wai iā ia.

② Hiki i ka Arc stabilizer ke hoʻopaʻa i ka pahu arc a hoʻemi i ka nui o ka spatter.

③ Ka hana hoʻohuihui Hiki i kekahi o nā mea hoʻohui i loko o ke kumu ke hoʻohui i ka weld.

④ Hiki i nā mea hoʻoheheʻe deoxidation o ka slag ke hana me nā metala wai.E hoʻomaikaʻi i ka hoʻohui ʻana o ka weld metala, hoʻomaikaʻi i kona ʻano mechanical.

Eia kekahi, hiki i ka slag uhi ke hoʻemi i ka helu hoʻoluʻu o ka wai i hoʻoheheʻe ʻia, e hoʻolōʻihi i ka manawa o ka wai i hoʻoheheʻe ʻia, he mea maikaʻi ia e hōʻemi i ka ʻike o ke kinoea ʻino i ka weld a pale i ka porosity.

He aha nā ʻano o ka flux cored arc welding i laila?

He ʻelua ʻano o ka flux cored wire arc arc welding (FCAW-G) a me ka pale ʻana iā ia iho (FCAW-S), ma muli o ka hoʻohana ʻia ʻana o ke kinoea pale waho a i ʻole.

Hoʻohana maʻamau ka hoʻoheheʻe ʻana i ke kinoea o ka uea flux-cored carbon dioxide a i ʻole carbon dioxide me argon ma ke ʻano he kinoea pale, a ʻo ka flux o ka uea he liʻiliʻi mea hoʻoheheʻe kinoea.Ua like kēia ʻano me ka hoʻoheheʻe ʻana i ka pale kinoea.ʻAʻole pono ke kinoea pale aku i waho.He nui ka nui o ka gasifier i ka flux, a ua hoʻohana ʻia ke kinoea a me ka slag decomposed e ka gasifier no ka pale.

He aha nā pōmaikaʻi o ka wiliwili arc-cored arc?

Loaʻa i ka Flux-cored arc welding nā pono aʻe.

(1) Kiʻekiʻe kuʻihao productivity kiʻekiʻe hehee ai i ka pono (a hiki i 85% ~ 90%), wikiwiki hoʻoheheʻe wikiwiki;No ka wiliwili pālahalaha, ʻo ka wikiwiki o ka uhi ʻana he 1.5 mau manawa ma mua o ke kuʻi lima arc manual, a no nā kūlana kuʻekuʻe ʻē aʻe, ʻo ia ka 3-5 mau manawa o ka kuʻihao arc manual.

② Pākī liʻiliʻi, weld e hana ana i ka lāʻau lapaʻau maikaʻi i hoʻohui ʻia i ka arc stabilizer, no laila ke kūpaʻa arc, ka pā liʻiliʻi, ka hana weld maikaʻi.No ka mea, ua uhi ʻia ka loko i hoʻoheheʻe ʻia me ka palau, ʻoi aku ka maikaʻi o ke ʻano o ka weld ma mua o ke kalapona kalapona.

(3) Kiʻekiʻe kuʻihao maikaʻi Ma muli o ke kinoea slag i hui pū ʻia, hiki iā ia ke pale aku i ke kinoea ʻino mai ke komo ʻana i ka wahi kuʻi.Eia kekahi, lōʻihi ka manawa o ka wai hoʻoheheʻe ʻia, kahi kūpono i ka ua hau, no laila he haʻahaʻa haʻahaʻa hydrogen ka weld a me ke kūpaʻa porosity maikaʻi.

(4) Strong adaptability wale pono e hoʻoponopono i ka haku mele 'ana o ka solder uea cored, hiki ke hoʻokō i nā koi o nā ʻokoʻa kila ma ka weld haku mele.

He aha nā hemahema o ka wiliwili arc-cored arc?

ʻO nā hemahema o ka flux-cored arc welding penei.

Ke hoʻohālikelike ʻia me ka welding pale kinoea, ʻoi aku ka kiʻekiʻe o ke kumukūʻai o ka wili welding a paʻakikī ke kaʻina hana.

② He paʻakikī ka hānai uea, pono e hoʻohana i ka mīkini hānai uea hiki ke hoʻoponopono pololei ʻia ke kaomi ʻana.

③ He mea maʻalahi ka pahu pahu e hoʻomohu i ka makū, no laila pono e mālama pono i ke kaula kuʻi.

④ Pono ka wehe ʻana o ka slag ma hope o ka wili ʻana.

⑤ Hoʻonui ʻia ka uahi a me nā kinoea ʻino i ke kaʻina hana kuʻi, no laila e hoʻoikaika ʻia ka ea.

He aha ke kinoea pale e hoʻohana mau ʻia i ka wiliwili arc-cored arc?He aha nā ʻano o kēlā me kēia?

Hoʻohana maʻamau ʻo Flux cored wire arc arc i ke kinoea carbon dioxide maʻemaʻe a i ʻole carbon dioxide a me ke kinoea argon ma ke ʻano he kinoea pale.Pono e koho ʻia ke ʻano kinoea e like me ka uea flux-cored i hoʻohana ʻia.

Hoʻopili maʻalahi ʻo Argon, no laila e maʻalahi ke hoʻokō i ka hoʻololi ejection ma argon arc.Inā ʻaʻole liʻiliʻi ka waihona argon o ka hui kinoea ma mua o 75%, hiki i ka flux cored wire arc welding ke hoʻokō i ka hoʻololi jet paʻa.Me ka emi ʻana o ka ʻike argon, piʻi ka hohonu o ke komo ʻana, akā e emi ana ke kūpaʻa arc a piʻi ka spatter rate.No laila, ʻo 75%Ar+25%CO2 ka hui kinoea maikaʻi loa.Eia kekahi, hiki ke hoʻohana ʻia ʻo Ar+2%O2 no ka hui kinoea.

Ke kohoʻia ke kinoea CO2 maʻemaʻe, e hoʻoheheʻeʻia ma lalo o ka hana a ka wela arc a hana i ka nui o nā oxygen atoms, e hoʻoheheʻe i ka manganese, silicon a me nā mea'ē aʻe i loko o ka wai i hoʻoheheʻeʻia, e alakaʻi ana i ke ahi o nā mea hoʻohui.No laila, pono e hoʻohana ʻia ka uea kuʻi me ka manganese kiʻekiʻe a me ka ʻike silika.

Ka manawa hoʻouna: Mei-09-2023